Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

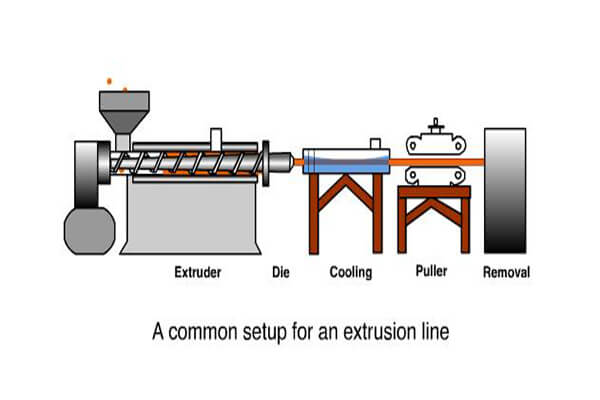

Extruder machines are used extensively in the plastics industry. The machine is utilized by plastic engineers to turn raw plastic pellets or granules into the processed forms. The resultant products include plastic sheets or long pieces such as gutters and pipes.

PVC extruder machines are highly efficient as the process high volumes which require only a little post-processing refinement.

When making different plastic products, the operating points of the extruder are different, but there are similarities. The following briefly introduces the same operating steps when extruding various products and the main points of the extruder that should be noted.

(1)The raw materials should meet the required drying requirements and further drying if necessary. And the raw materials are sieved to remove agglomerates and mechanical impurities.

(2)Check whether the water, electricity and gas systems in the equipment are normal to ensure that the water and gas paths are unobstructed, that the electrical system is normal, that the heating system, temperature control, and various instruments are working reliably.

(3)Install the tube extrusion machine head and setting sleeve. According to the product's variety and size, choose the specifications of the machine head. Install the machine head in the following order.

(1)You can drive after the temperature is constant. Tighten the bolts of the machine head and the extruder flange again before driving to eliminate the difference in thermal expansion between the bolts and the machine head. The order of tightening the machine head bolts is diagonal, and the force should be uniform. When tightening the flange nut of the machine head, the tightness around the four sides is required, otherwise, the material will run away.

(2)To drive, first press the "ready to drive" button, then connect to the "drive" button, and then slowly rotate the screw speed adjustment knob to start the screw speed slowly. Then gradually speed up while adding a small amount. Pay close attention to the change of the indication of the host ammeter and various indication meters when feeding.

(3)When the die is uniformly discharged and plasticized well, the styling sleeve can be pulled. Judgment of plasticization degree should be based on experience. Generally, it can be judged based on the appearance of the extruded material, that is, the surface is shiny, no impurities, no foaming, coke and discoloration. The burrs and cracks have some elasticity, which indicates that the material is well plasticized. If the plasticization is not good, the screw speed, barrel and head temperature can be adjusted appropriately until it meets the requirements.

(4)During the extrusion production process, it is necessary to regularly check whether the various process parameters are normal according to the process requirements and fill in the process record sheet. Check the quality of the profile products according to the quality inspection standards, and take timely solutions when problems are found.