Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

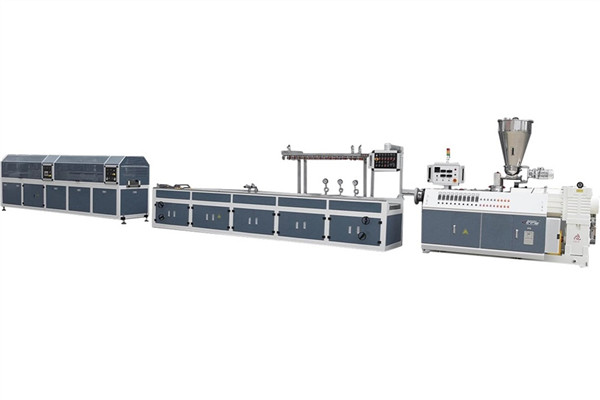

The innovative design of building materials such as the door and window profiles has added to the aesthetics of recent structures; both in the residential and commercial buildings. Such materials like the PVC door and window profiles have been made available with a special equipment; the PVC window profile extrusion machine.

In the production of plastics, different types of equipment are used. The two major machines include the extruder machine and the injection mold. In this post, we will be focusing on the relationship between the extruder machine and the injection mold in the production of the window and door plastic profile.

Let's get started!

To obtain the structure of the window profile both machine (the extruder and mold) are designed with screw and barrel which are used to convey the plastics.

However, in the case of the extruder, the diameter of the screw and the L/D ratio are relatively larger.

During the production of the plastic profiles, the extruder engages in the continuous extrusion of the plastics through a die head to obtain the product. The products formed through this extrusion process include plastic bars, plastic sheets as in the window and door profiles and plastic pipes.

In the case of the injection mold, the process is not a continuous one. Here, the plastics are injected into the closed cavity until the cavity is filled to capacity. Now, the machine stops while the formed plastic in the mold is cooled to obtain the shape.

The mold commences work when the shaped plastic is removed from the open mold. When it comes to the structure the injection mold machine is used to obtain relatively complex structures such as shell, pot, plastic cups and more.

Today, there are different PVC window profile extrusion machine manufacturers. However, it is important to liaise with a competent manufacturer to ensure that you get a top quality equipment for your PVC production needs. Before hiring any manufacturer, it is important to go through some background check on their competence and their reputation. You can do this by accessing their website to have good knowledge of their specialty. Also, you can ask for reviews from past clients who have dealt with them in the past. This is sure to afford you ample knowledge to make an informed decision.

You can find a wide range of different PVC extrusion machines in our PVC window profile extrusion machine factory. However, when making your choice of machine, you need to consider some factors. These factors include the quality of the machine, the price including shipping cost, the size with respect to the installation space, maintenance requirements, after-sales services of the supplier and more.

You need to ensure that your budget is enough to secure a high quality PVC window extrusion machine to obtain the best production result. A top quality machine will save excessive maintenance and repair cost while increasing the efficiency of the production process.