Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

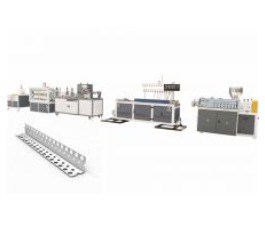

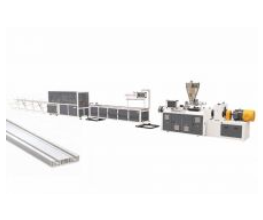

Let me introduce to you the working standards of our company's PVC profile production line.

1. Accessory process

1-1 The batching personnel must receive a sufficient amount of raw materials in the warehouse. During the batching period, the raw materials in the bag must be cleaned, and no surplus should be left.

1-2 Strictly check and weigh the materials in strict accordance with the requirements of the formula sheet issued by the production management department and the specified weight.

1-3 After all the raw materials are checked, the different raw materials shall be mixed in a fixed container according to the requirements in proportion to the capacity of each mixing drum of the mixer strictly according to the unit.

2. Mixing process

2-1 Start the mixer. Fill the prepared raw materials into the hot mixing drum of the mixer in order.

2-2 Control the temperature of the foot plate of the hot mixing drum. When the temperature reaches the standard temperature specified in the process, put the raw materials into the cold mixing drum to continue mixing.

2-3 Control the mixing temperature of the cold mixing drum. When the mixing temperature is cooled to the standard temperature required for production, put the mixed raw materials into the storage box of the elevator.

2-4 Check whether the sieve leakage meets the quality standard. If it is unqualified, shut down the raw materials in the storage tank in time and return the raw materials in the storage tank to the mixer to re-mix as required.

3. Feeding process

3-1 Before starting the hoist, the empty storage tank must be accurately placed at the outlet of the vibrating screen (absolutely aligned with the outlet, no deviation is allowed).

3-2 After the hoist is started, the feeder insists on staying at the discharge port and observes that the raw material in the storage tank is filled to the required capacity, and then informs the mixer in time to stop the operation of the hoist.

3-3 Check whether the raw materials in the storage tank circulate smoothly in a sequential cycle. If it is not smooth, take effective measures to deal with it in time.

4. Basic process

4-1 According to the requirements of the model and specifications of the production product, install the extrusion die and the shaping die that meet this product specification.

4-2 Check whether the instruments, electrical appliances, and mechanical facilities of the operating equipment are in a normal state, check whether the raw material supply is in place, and whether the raw material composition meets the required composition of the product.

4-3 Check whether the vacuum pump is normal, check whether the tractor is running normally, whether the gas path of the tractor is unblocked, check whether the cutting machine is running normally, whether the gas path is unblocked, and check whether the gas path of the unwinding rack is unblocked.

4-4 Start production. Correctly operate the extrusion equipment and adjust the relevant data to ensure product quality. After the product is formed, the quality inspector will be notified for inspection, and normal production will occur after the quality inspection is passed.

5. Finished product process

5-1 Remove qualified products from the PVC profile extrusion line in order.

5-2 Pack the finished products according to the required quantity, and paste relevant signs.

5-3 Transport the packaged finished products to the designated place and place them neatly as required.

5-4: Transport the unqualified products to the recycling workshop and put them in order.

6. Recycling process

6-1 Crack the extruded materials and stack them neatly.

6-2 Crush the recycled materials of different colors separately and pack them into bags.

6-3 Grind the pulverized recycled materials according to different colors, respectively check the catties and bag them, send them to the mixing place for orderly placement, and notify the mixing personnel to receive and complete the procedures.

The above is a series of working standards of our company's PVC profile extrusion line. We hope to make you more familiar with our PVC profile extrusion line. If you want to buy our products, you are welcome to contact us.