Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

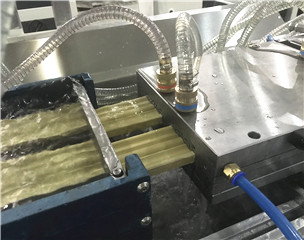

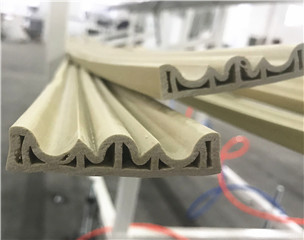

This WPC(PVC) profile extrusion line is used for producing WPC (PVC) door frame.

The customer purchased two sets production lines, and he has two products are produced from two separate production lines. We met the customer in fair.

As this is the first project for customer, at the beginning, he wants only one line to produce some different products, but he also want the high capacity for big size product; during our discussion, we gave the advice to him bigger capacity extruder.

So he ordered two sets production lines, one is SJSZ65/132 and another one is SJSZ80/156.

Raw material : WPC (PVC) powder

Extruder: conical twin screw extruder SJSZ65/132 or SJSZ80/156

Wood plastic composite is based on high density polyethylene and wood fiber, which determines that it has some characteristics of plastic and wood.

1) Good processing performance

Wood plastic composite material contains plastic and fiber, so it has the same processing performance as wood. It can be sawn, nailed and planed. It can be finished by using woodworking tools, and the nail holding force is obviously better than other synthetic materials. The mechanical properties are better than that of wood materials. The nail holding force is generally 3 times that of wood and 5 times that of particleboard.

2) Good strength performance

Wood plastic composite material contains plastics, so it has better elastic modulus. In addition, it contains fiber and is fully mixed with plastic, so it has the same physical and mechanical properties as hardwood, such as compression resistance and bending resistance, and its durability is significantly better than ordinary wood materials. The surface hardness is high, generally 2-5 times that of wood.

3) Water and corrosion resistance, long service life

Compared with wood, wood plastic materials and their products are resistant to acid and alkali, water and corrosion, and do not breed bacteria, are not easy to be mothed and do not grow fungi. Long service life, up to more than 50 years.

4) Excellent adjustable performance

With the aid of additives, plastics can be changed by polymerization, foaming, curing and modification, thus changing the density and strength characteristics of wood plastic materials, and achieving special requirements such as anti-aging, antistatic, flame retarding and so on.

5) It has UV light stability and good colorability.

6) Its biggest advantage is to turn waste into treasure, and can be 100% recycled. It can be decomposed without causing "white pollution" and is a real green environmental protection product.

7) Wide sources of raw materials

The plastic raw materials for the production of WPC are mainly high-density polyethylene or polypropylene. The wood fiber can be wood powder, rice bran or wood fiber. In addition, a small amount of additives and other processing aids are needed.

8) It can be made into any shape and size as required.