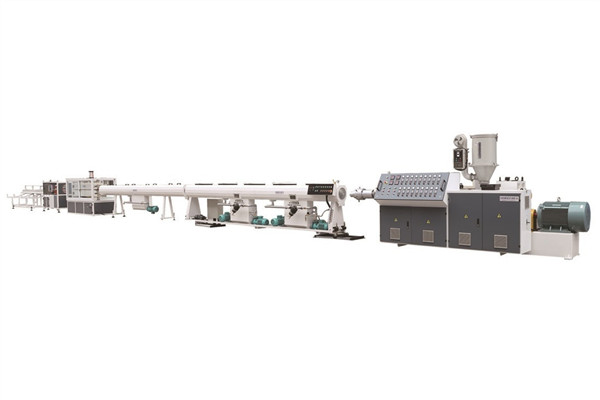

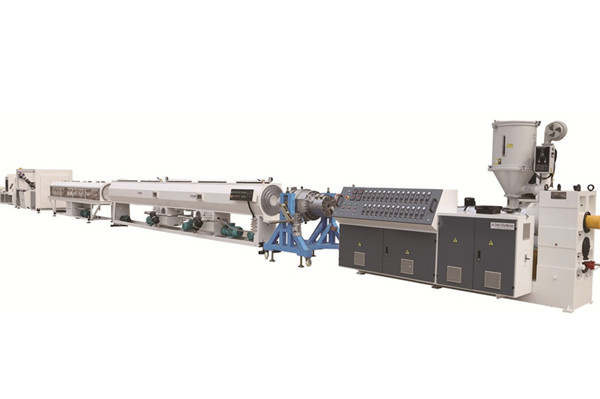

Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

This production line includes Single screw extruder, mould, vacuum calibration tank, water cooling tank, haul-offs, Cutting machine, stacker, winder.

Extruder with common speed and high speed for option; High speed extruder adopts high efficiency screw. there are different models extruders for choice.

Single layer pipe, multilayer pipe for producing. The whole production line can be choosed by manual operation or PLC control.

| Extruder model | SJ65/33 |

| Motor power | 37kw, 45kw, 55kw |

| Diameter of HDPE pipe | 16mm, 20mm, 25mm, 32mm, 40mm, 50mm, 63mm, 75mm, 90mm, 110mm |

| Length of vacuum calibration tank | 6000mm |

| Haul-offs | two caterpillars or belt |

| cutting | non-sawdust cutting |

| Winder | Single disk or double disk |

| Stacker length | 6000mm |

| Extruder model | SJ65/33 |

| Motor power | 55kw |

| Diameter of HDPE pipe | 63mm,75mm, 90mm, 110mm,160mm |

| Haul-offs | Three caterpillars |

| cutting | non-sawdust cutting or planetary cutting |

| Stacker length | 6000mm |

| Extruder model | SJ75/33 |

| Motor power | 90kw or 110kw or 132kw |

| Diameter of HDPE pipe | 75mm, 90mm, 110mm, 125mm,160mm, 200mm, 225mm, 250mm |

| Haul-offs | Three caterpillars |

| Cutting | Planetary cutting |

| stacker length | 6000mm or 8000mm |

| Extruder model | SJ90/33 |

| Motor power | 110kw or 160kw |

| Diameter of HDPE pipe | 110mm, 125mm,160mm, 200mm, 225mm, 250mm,315mm |

| Haul-offs | Four caterpillars |

| Cutting | Planetary cutting |

| stacker length | 8000mm |

| Extruder model | SJ90/33 |

| Motor power | 110kw or 160kw |

| Diameter of HDPE pipe | 225mm, 250mm, 315mm, 400mm, 450mm |

| Haul-offs | four caterpillars |

| Cutting | planetary cutting |

| Length of vacuum tank | 8000mm |

| Extruder model | SJ120/33 |

| Motor power | 160kw |

| diameter of HDPE pipe | 315mm, 400mm, 450mm, 500mm, 630mm |

| Vacuum calibration tank | 2000mm + 8000mm |

| Haul-offs | Six caterpillars |