Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

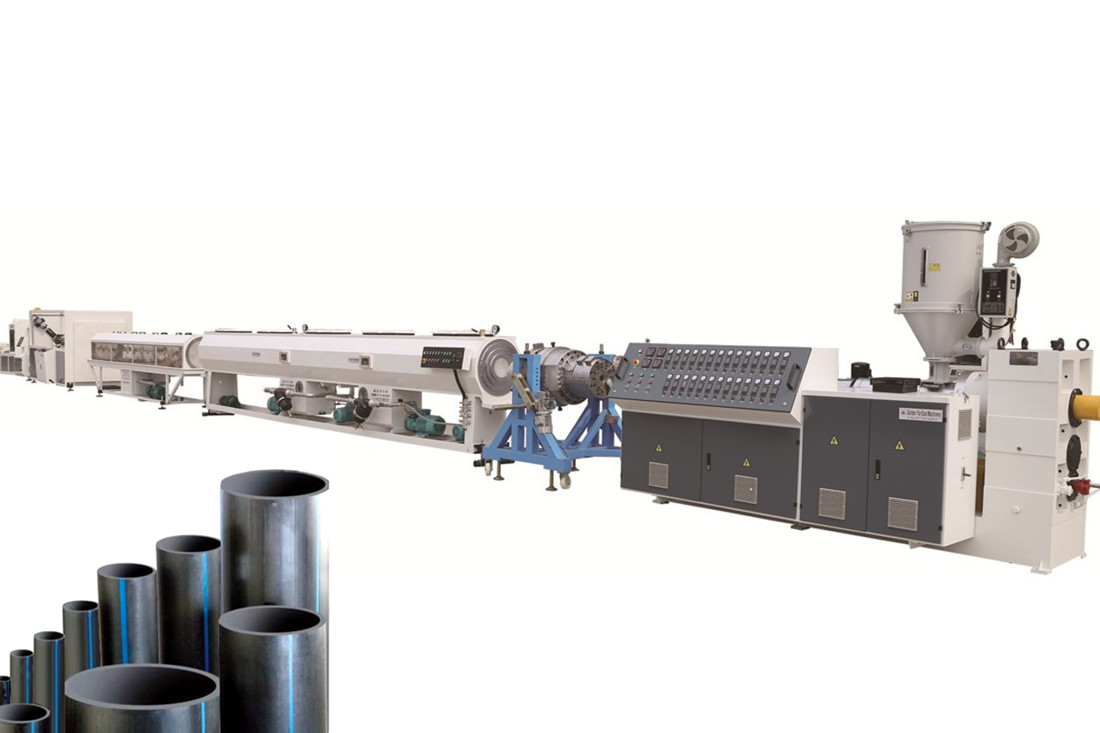

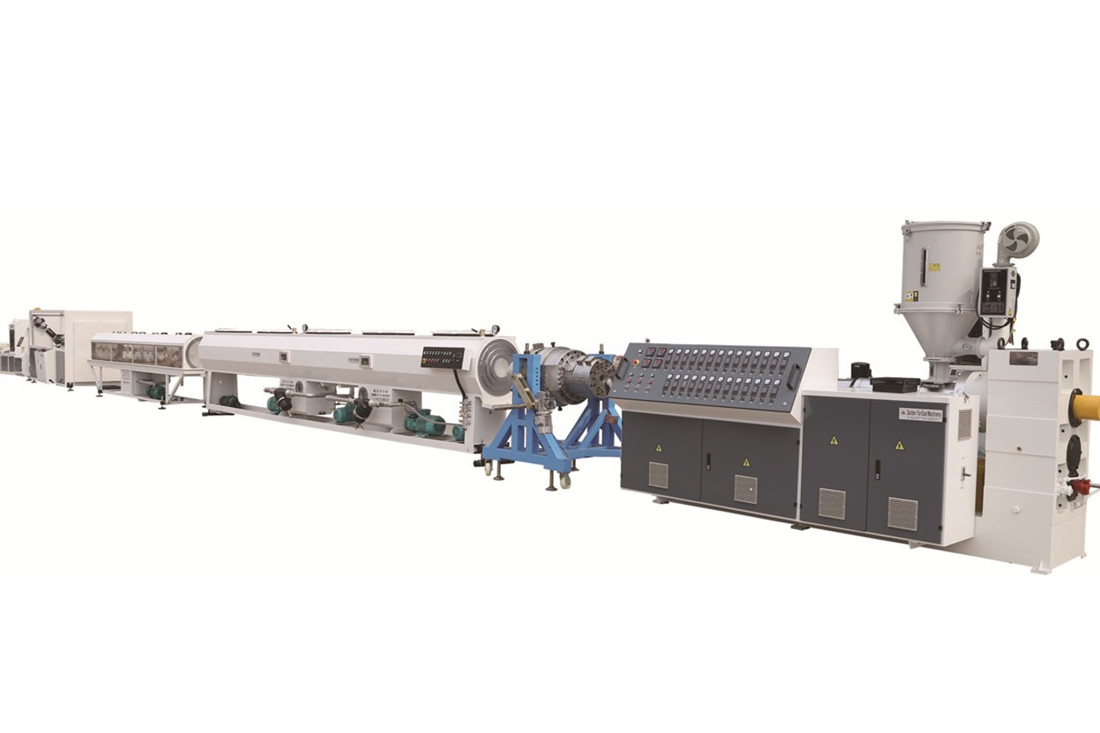

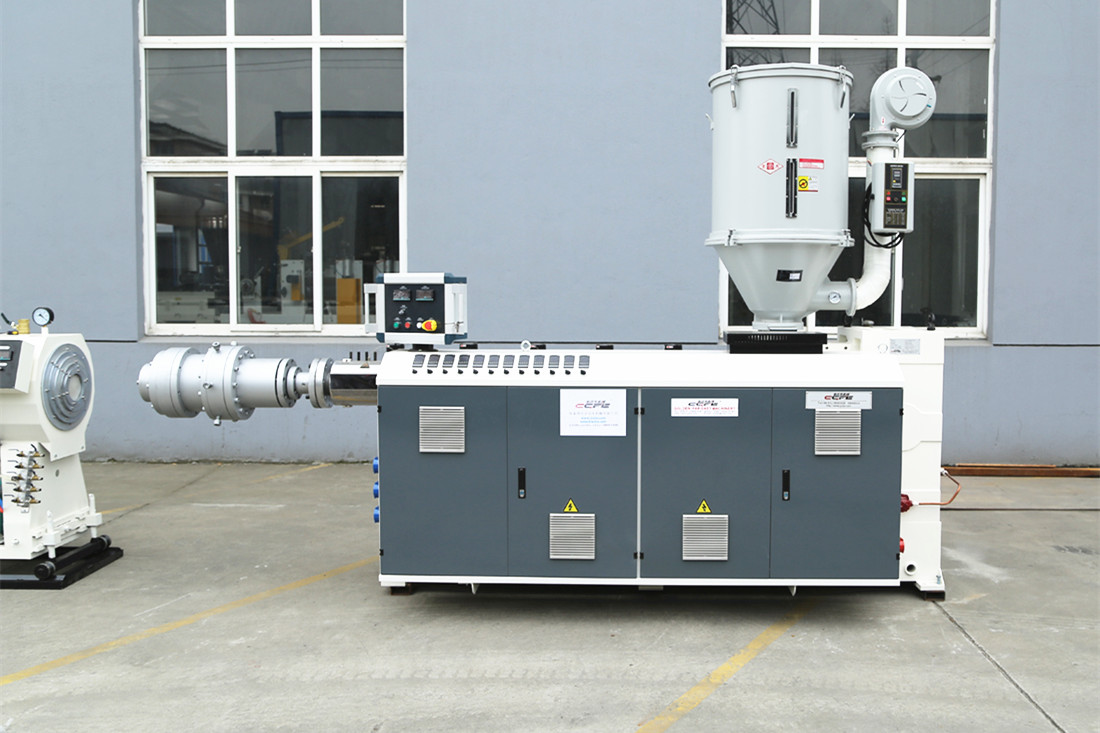

The screw uses comprehensive mixed part with belt barrier and mixed melting head, new pattern notch barrel makes good performance of plasticizing and mixed melting. It ensure high speed and good performance extruding. It is also equipped with special extruder with marking line, PE large caliber and thick wall pipe die head adopts lastest spire or basket-like type technique that makes sure a stable and credible extruding. It adopts water film lubricating and hydroseal cooling system to suit for the material requirement of PE. Make sure the stabilization of diameter and round degree when producing thickness wall pipe at high speed. The special designed multilevel vacuum and cooling device and especial high pressure cooling system ensure the extrusion of big caliber and high pressure degree PE pipe stuff. The puller includes three, four and six claw puller according to pipe specification. It adopts superfine speed regulating system that ensures an stable and credible operating. The cutter adopts planetary cutter which has a higher automatization of computer control and avoid to longer period of maintenance.

Pipe diameter(mm) | 16 – 63 | 63 – 160 | 75 – 250 | 110-315 | 315-630 | 450-800 | 710-1200 |

Extruder (ET-S) | 65/33 | 70/33 | 75/33 | 90/33 | 120/33 | 150/33 | 150/33 |

Main motor power(kw) | 37/45 | 45 | 90 | 132 | 185 | 385 | 415 |

Length of vacuum tank(mm) | 6000 | 6000 | 6000 | 8000 | 2000+10000 | 2000+12000 | 2000+12000 |

Length of cooling tank(mm) | 6000 | 6000 | 6000×2 | 6000×2 | 6000×2 | 6000×3 | 6000×3 |

Puller | 2claw | 3claw | 3claw | 4claw | 6claw | 8claw | 8claw |

Max. Capacity (kg/h) | 80 | 180 | 300 | 450 | 600 | 1000 | 1000 |

PE pipe production line mainly used in producing of HDPE pipes with various tube diameter and wall thickness in the aspects such as the agricultural, constructional, and cable laying etc. the unit is composed of the conical twin-screw extruder, vacuum modes such as two claw, three claw and so on.

PE pipe for sewage is also called HDPE pipe. This kind of pipe is often used as the first choice for municipal engineering, mainly used in: sewage treatment industry. Because of its wear-resistant, acid resistant, corrosion-resistant, high temperature resistant, high-pressure resistant and other characteristics, it gradually replaced the position of traditional pipes such as steel pipes and cement pipes in the market, especially because of its light weight and convenient installation and movement, which is the first choice of new materials. Users should pay special attention to the following points when selecting pipes of this material:

1. Special attention should be paid to the selection of raw materials for plastic pipes. There are thousands of brands of polyethylene raw materials, and there are raw materials as low as several thousand yuan per ton on the market. The products produced from this raw material can not be constructed, otherwise the rework loss will be huge.

2. The selection of pipeline manufacturers shall be subject to the standard professional manufacturers.

3. When choosing to purchase PE pipes, the manufacturer shall be inspected on the spot to see if it has the production capacity.

Wooden pallet, PE film package.