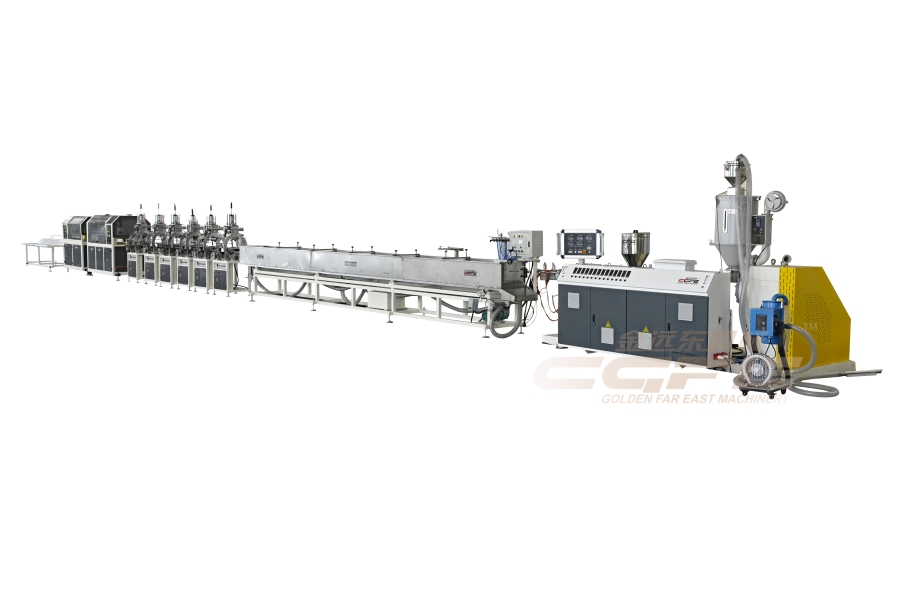

Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

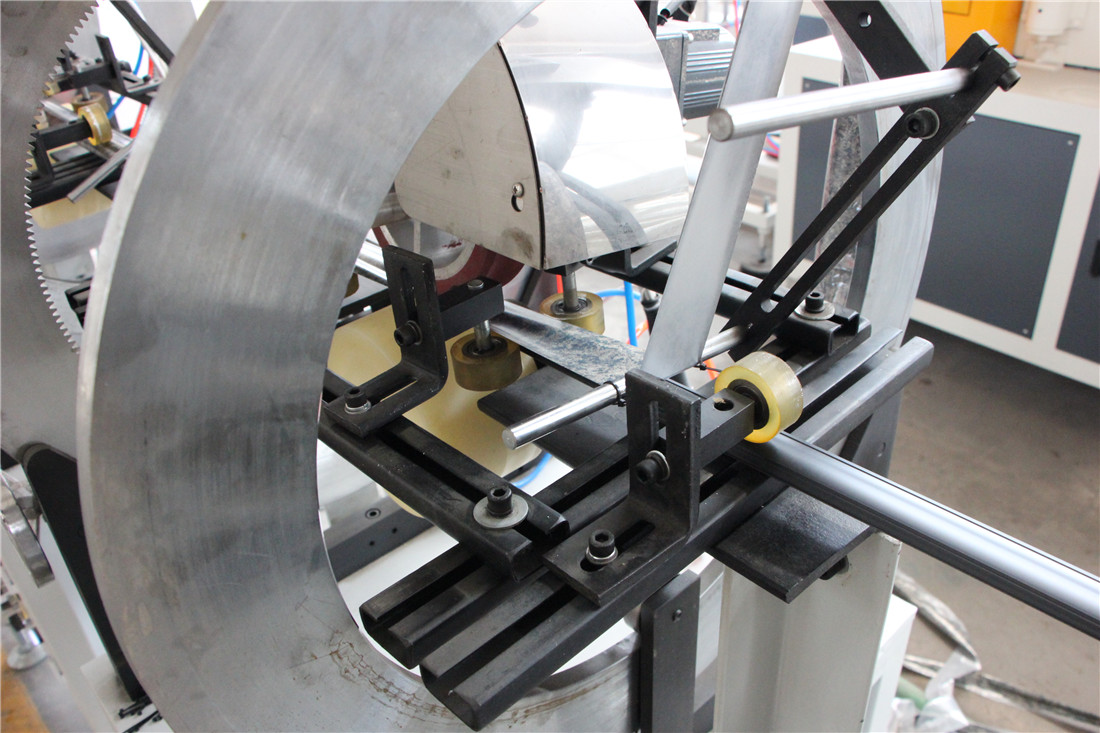

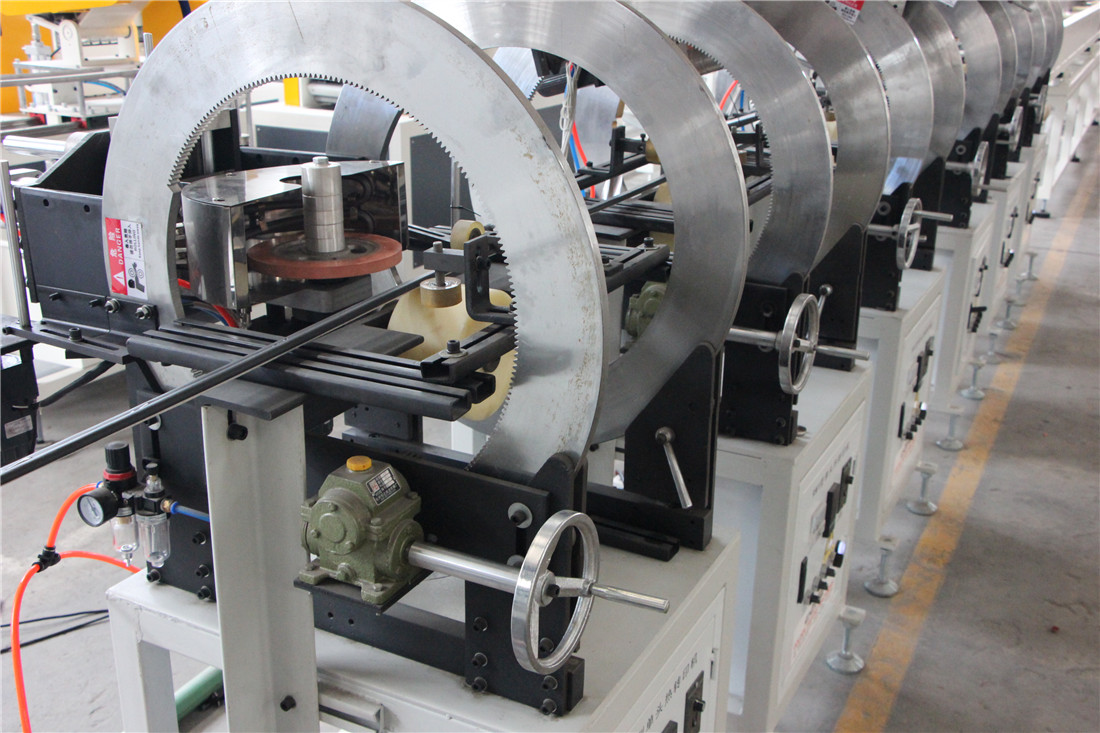

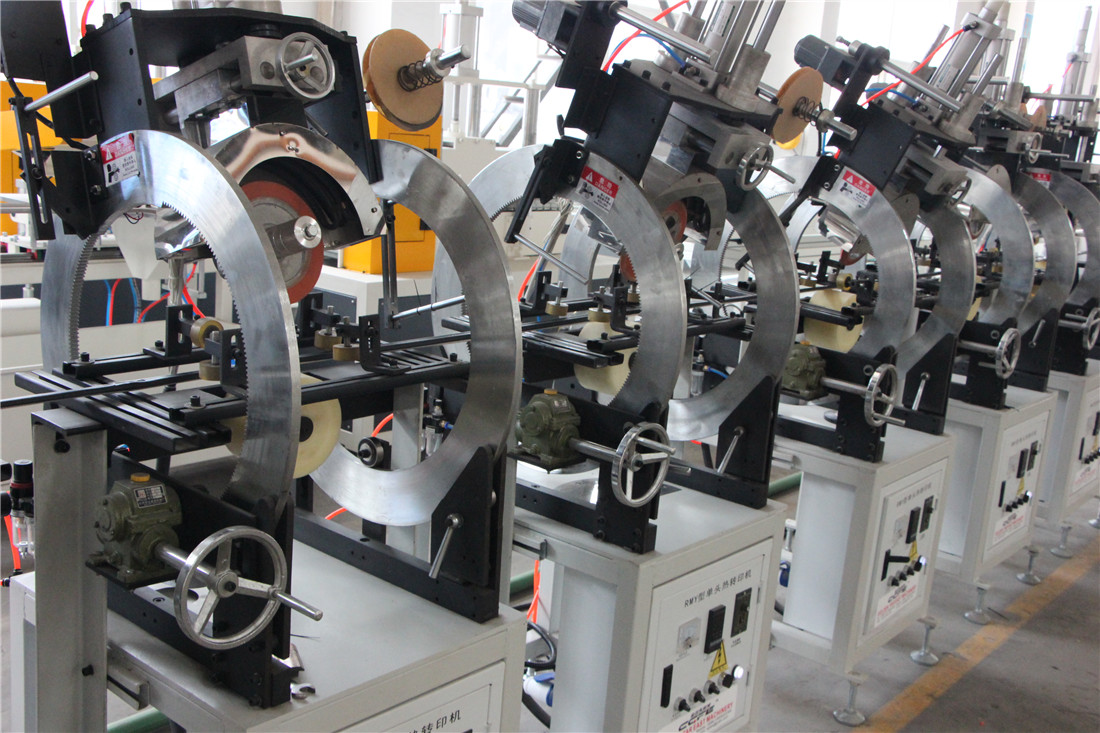

PS Foaming Profile Production Line advantages of this production line are as follows: easy foaming, high efficiency and low production cost, etc. The production line has won a high reputation among our customers because of high automation, easy operation, and continuous production stable and reliable.

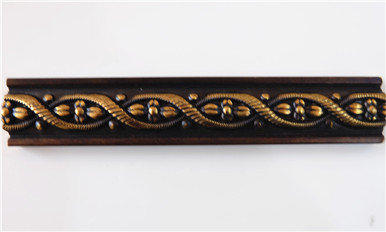

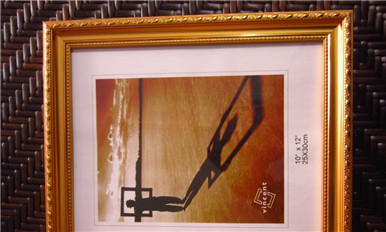

Picture frame, Photo frame, Mirror frame, Decoration Frame Etc.

Packaged by PE film, wood pallet.