Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

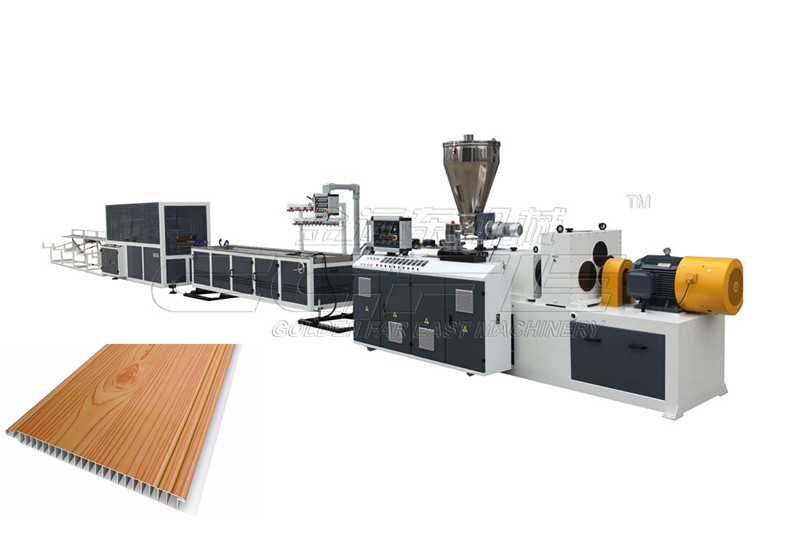

In the ever-evolving world of manufacturing, innovation is key to staying ahead of the competition. One such innovation that has revolutionized the production of plastic pipes is the Plastic Pipe Extrusion Line. This advanced technology has transformed the way plastic pipes are manufactured, offering numerous benefits in terms of efficiency, quality, and cost-effectiveness.

The Plastic Pipe Extrusion Line has significantly enhanced the efficiency of plastic pipe production. By automating the extrusion process, it eliminates the need for manual labor, reducing the chances of human error and increasing productivity. The line is equipped with state-of-the-art machinery and computerized controls, allowing for precise control over the extrusion parameters. This ensures consistent production of high-quality plastic pipes with minimal wastage.

With the Plastic Pipe Extrusion Line, manufacturers can now produce plastic pipes of superior quality. The automated process ensures uniform wall thickness, smooth surfaces, and accurate dimensions, resulting in pipes that meet the highest industry standards. Moreover, the line can handle a wide range of plastic materials, including PVC, PE, and PP, allowing for the production of pipes with varying properties to suit different applications.

The Plastic Pipe Extrusion Line offers significant cost savings for manufacturers. By streamlining the production process and reducing the need for manual labor, it cuts down on labor costs and increases overall efficiency. Additionally, the precise control over extrusion parameters minimizes material wastage, further reducing production costs. The line also has a high production capacity, allowing for large-scale production, which translates into economies of scale and lower per-unit costs.

One of the key advantages of the Plastic Pipe Extrusion Line is its versatility and ability to customize pipe production. The line can be easily adjusted to produce pipes of different sizes, diameters, and thicknesses, catering to a wide range of applications. Whether it's for plumbing, irrigation, or industrial purposes, the line can meet the specific requirements of different industries. This flexibility allows manufacturers to cater to diverse customer needs and expand their product offerings.

In addition to its numerous operational benefits, the Plastic Pipe Extrusion Line also contributes to environmental sustainability. The line utilizes advanced recycling technologies, enabling the use of recycled plastic materials in pipe production. This helps reduce the dependence on virgin plastic and promotes the circular economy. Furthermore, the precise control over extrusion parameters minimizes material wastage, reducing the overall environmental impact of the manufacturing process.

The Plastic Pipe Extrusion Line has revolutionized the production of plastic pipes, offering enhanced efficiency, improved quality, cost-effectiveness, versatility, and environmental sustainability. With its advanced technology and automated processes, it has become an indispensable tool for manufacturers in the plastic pipe industry. As the demand for plastic pipes continues to grow, the Plastic Pipe Extrusion Line will play a crucial role in meeting the industry's needs and driving further innovation.