Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

PS photo frame is a common type of photo frame made of polystyrene (PS) material. In the production process, there are multiple links and steps involved, from the procurement of raw materials to the production of final products. This article will analyze in detail the entire PS photo frame production line process, including raw material preparation, injection molding, surface treatment, assembly and quality control.

Raw material procurement: First of all, the production line needs to purchase polystyrene (PS) particles as the main raw material. These pellets are usually purchased from suppliers, who will provide suitable PS pellets based on the needs of the production line.

Raw material quality inspection: Before using PS granules, they need to be inspected for quality. This includes checking the appearance, size and chemical properties of the particles. Only particles that pass quality inspection can enter the next step of the production process.

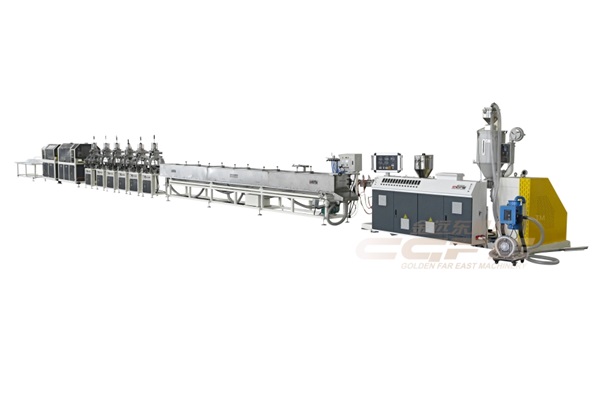

Injection molding machine operation: Put the PS granules that have passed the quality inspection into the hopper of the injection molding machine. The injection molding machine heats and melts the particles and injects the molten PS into the mold. The design of the mold determines the shape and size of the final picture frame.

Cooling and solidification: During the injection molding process, the molten PS cools and solidifies in the mold. This usually takes some time to ensure the finished product has the required hardness and stability.

Mold Removal and Trimming: Once the PS frame has cured, it needs to be removed from the mold. This often requires the use of specialized tools and equipment. The edges of the frame may then need to be trimmed to ensure a neat appearance.

Sanding and polishing: In order to make the surface of the PS photo frame smooth and flawless, sanding and polishing is required. This can be done by using tools and materials such as sandpaper, grinding wheels, and polishes.

Decoration and decorative parts installation: During the production process of PS photo frames, decorations and decorative parts can be added as needed. This may include adding decorative graphics, stickers, metal frames, etc.

Installing the back panel and glass: In order for the picture frame to have a complete structure, the back panel and glass need to be installed. Backsheets are usually made of cardboard or plastic, while glass needs to be transparent and wear-resistant.

Appearance inspection: At different stages of the production line, PS photo frames need to be inspected for appearance. This includes checking for defects such as cracks, scratches, bubbles, etc.

Size and stability test: The size and stability of the PS photo frame are key indicators of its quality. The production line requires dimensional measurements and stability testing to ensure each frame meets the required standards.

The production line of PS photo frames involves multiple key links and steps, from the preparation of raw materials to the production of final products. Through strict quality inspection and quality control, we can ensure that the PS photo frame has good appearance and stability. While continuously improving and optimizing the production line, production efficiency and product quality can also be improved to meet market demand.

Golden Far East Machinery Co., ltd. is a high-tech enterprise which is specialized in research, manufacture and marketing plastic extrusion lines.We are here to serve you with our best services.