Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

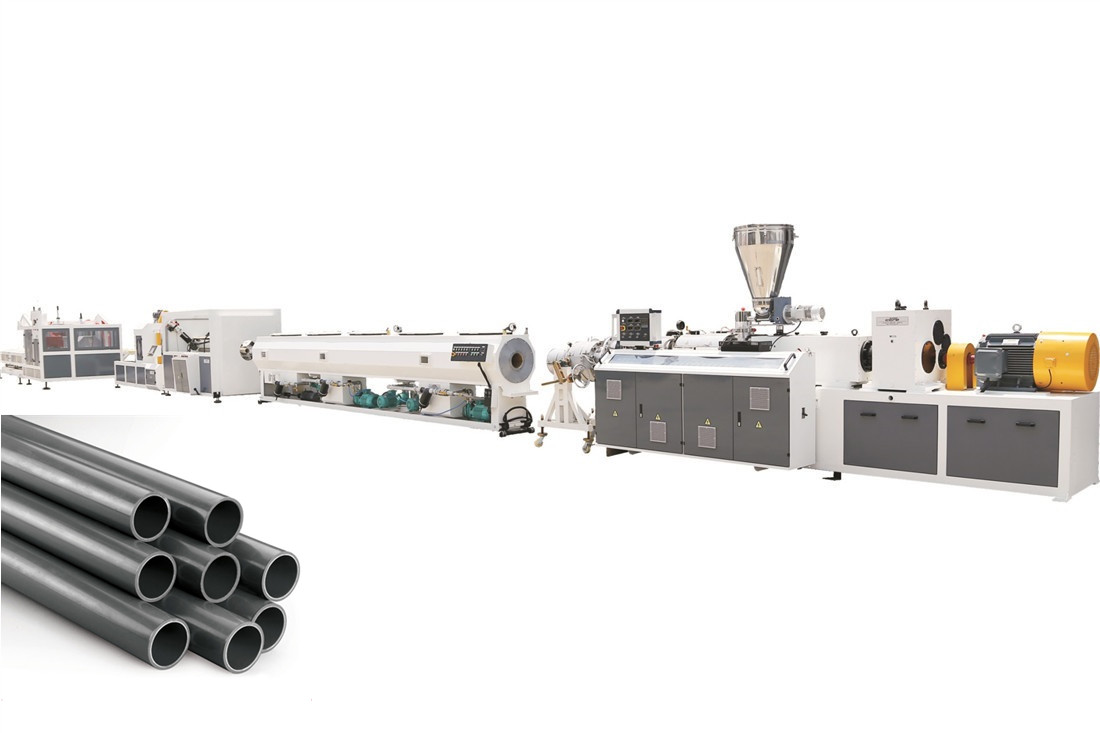

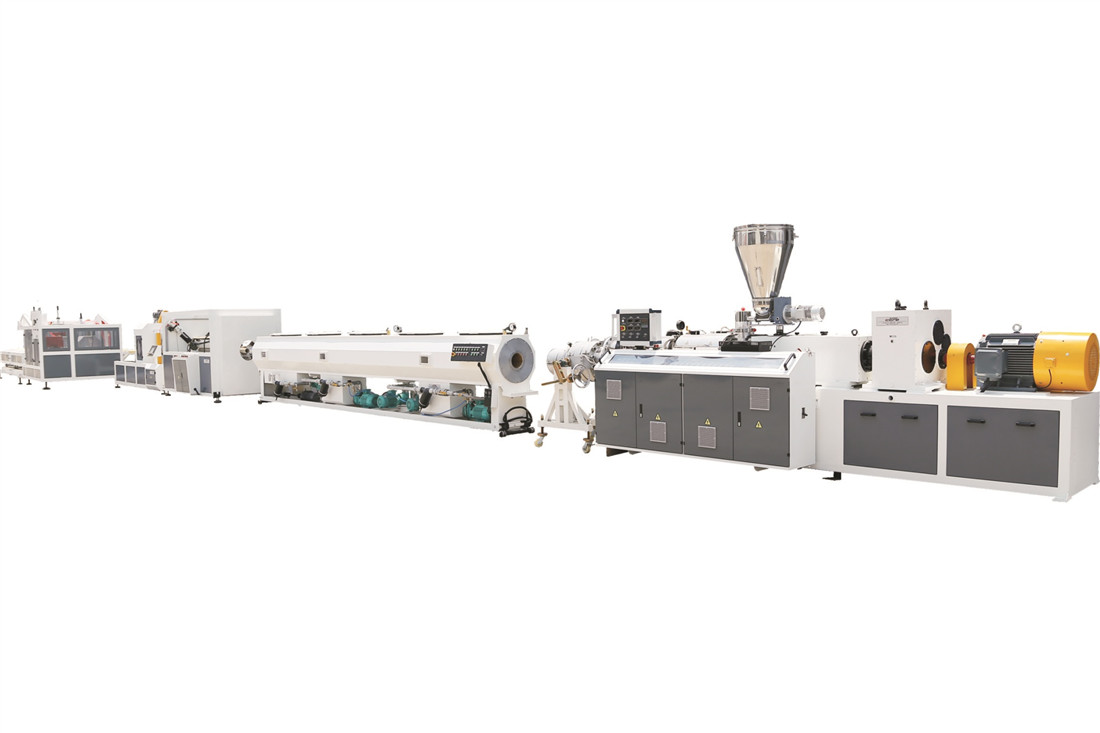

This production line is mainly used in producing of PVC pipes with various tube diameter and wall thickness in the aspects such as the agricultural, constructional, and cable laying etc. the unit is composed of the conical twin-screw extruder, vacuum modes such as two claw, three claw and so on. Choose the saw blade cutting type or the planetary cutting type. It is additionally attached manufacturer of the inner wall spiral coil according to the client requirements. Produce inner wall spiral pipe, inner wall hollow and core foam pipe, ect. The planetary cutting machine is fully automatic computer control, it has such advantages of simple operation, reliable property, ect. It has reached world advanced level.

Pipe diameter | 50mm-110mm |

| Extruder model | ET-D65/132 |

| length of vacuum calibration tank | 6000mm |

| Puller | 3 claw |

| cutting | planetary cutting |

| belling type | U type R type J / Blowing type |

(1) Raw material mixing: PVC stabilizer, plasticizer, antioxidant and other auxiliary materials are added into the high-speed mixer according to the proportion and process, the materials are heated to the set process temperature by self friction between materials and machinery, and then the materials are reduced to 40-50 degrees by the cold mixer, so that they can be added into the hopper of the extruder.

(2) Extruder part: This machine is equipped with quantitative feeding device, so that the extrusion amount and feeding amount can match, to ensure the stable extrusion of products. Because of the characteristics of the conical screw, the feeding section has a large diameter, and the heat transfer area and shear speed of the material are relatively large, which is conducive to the plasticization of the material. The screw diameter of the metering section is small, reducing the heat transfer area and the shear speed of the melt, so that the melt can be extruded at a lower temperature. When the screw rotates in the barrel, the PVC mixture will be plasticized and pushed to the head of the machine, so as to achieve the purpose of compaction, melting, mixing and homogenization, and to achieve the purpose of exhaust and dehydration. The feeding device and screw drive device adopt frequency conversion speed regulation, which can realize synchronous speed regulation.

(3) Extrusion die part: PVC after compaction, melting, mixing and homogenization. There are follow-up materials pushed to the die by screw. The extrusion die is the key component of pipe forming.

(4) The vacuum setting water tank is used for the setting and cooling of pipes. The vacuum setting water tank is equipped with a vacuum system and a water circulation system for setting and cooling. The stainless steel box body is equipped with circulating water spray cooling. The vacuum setting water tank is equipped with a front and rear moving device and a left and right, high and low adjustment manual device.

(5) The traction machine is used to continuously and automatically lead the cooled and hardened pipes out of the machine head and adjust the speed by frequency conversion.

(6) Cutting machine: after controlled by the travel switch according to the required length, it will cut automatically, turn over the rack in time delay, and carry out flow production. The cutting machine will complete the whole cutting process with the instruction of the switch signal of the fixed length worker, keep synchronous with the pipe operation in the cutting process, and the cutting process will be driven by electric and pneumatic, The cutting machine is equipped with a dust absorption device to suck out and recover the debris produced by cutting in time.

(7) The turning operation of the turning frame is realized by the air cylinder through the control of the air circuit. The turning is equipped with a limit device. When the pipe is cut by the cutting saw, the pipe will continue to be transported. After the delay, the air cylinder will enter the work to realize the turning operation and achieve the unloading purpose. After unloading, reset automatically after a delay of several seconds, waiting for the next cycle [2].

PVC pipe material refers to PVC resin powder as the main raw material for pipe material. The types of PVC pipes are generally divided by the use of pipes: drainage pipe, water supply pipe, electric wire pipe, cable protective sleeve

Because the raw material formula is different, and the compressive strength of various types of pipes and other indicators are different.

PVC water supply pipe is used for building water supply works with water supply fittings.

PVC drainage pipe is used for drainage and sewage.

wooden pallet, PE film package.