Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

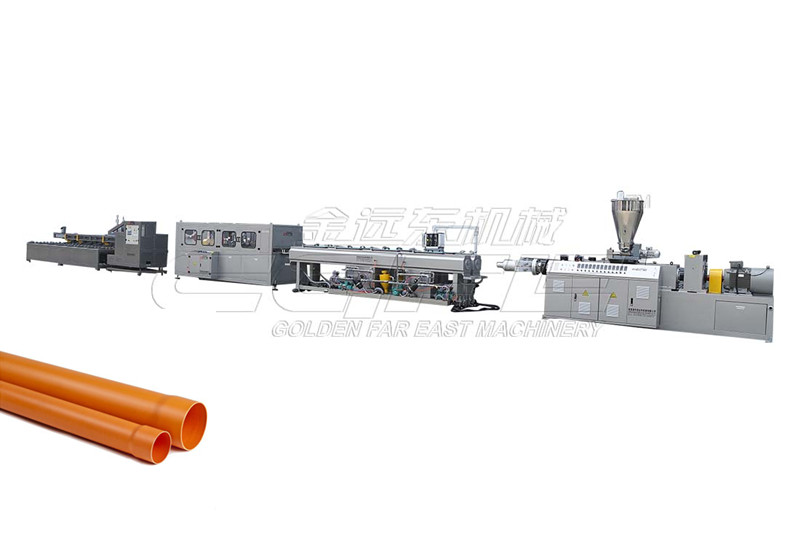

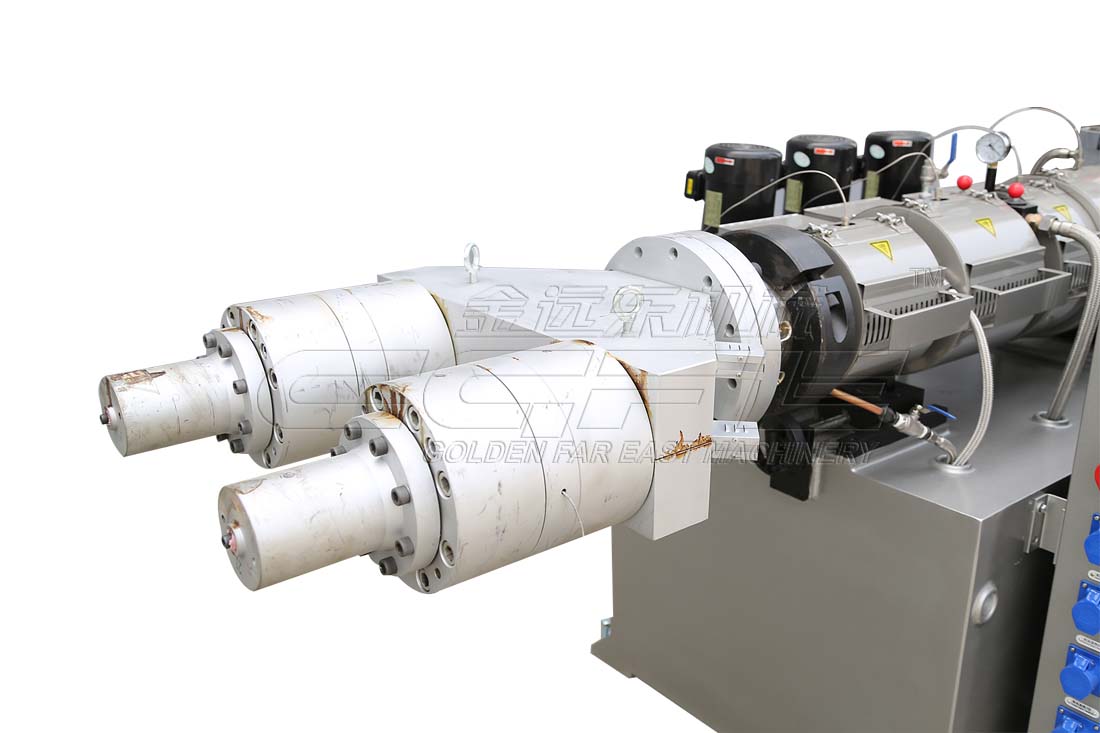

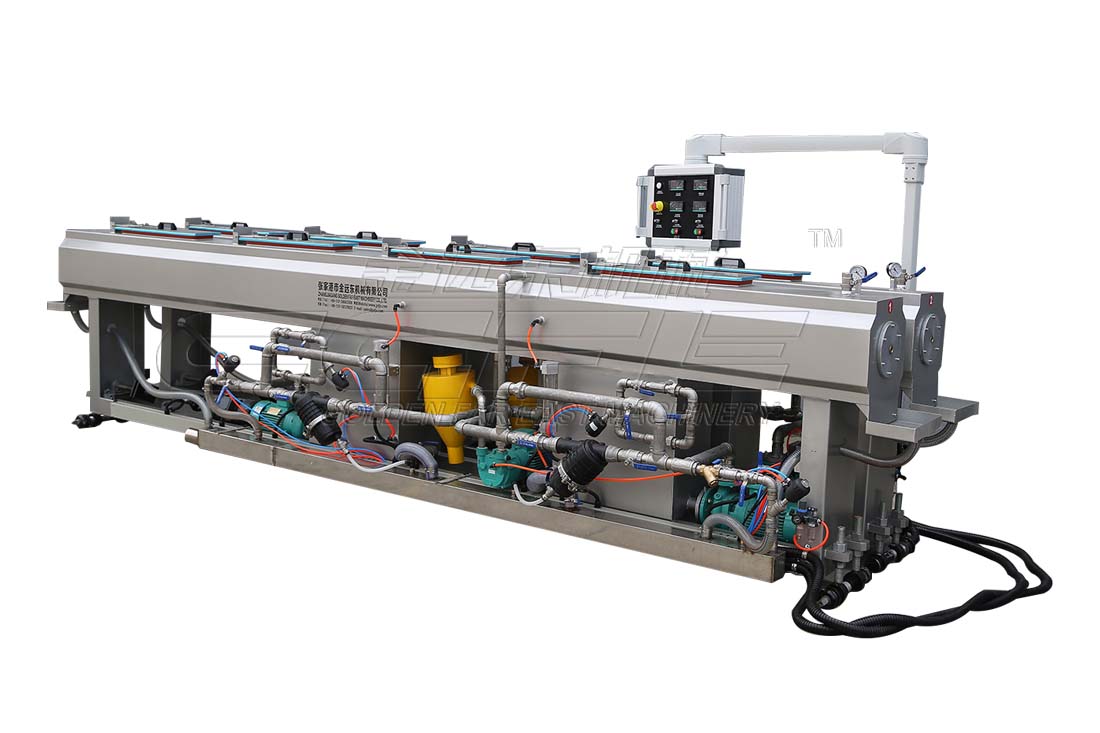

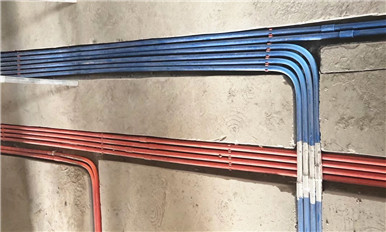

The pvc pipe production line is developed with 1990s advanced technology of Europe by our company. The main machine is conical twin screw extruder with three models to options. Equipped with dual pipe single-control vacuum calibration tank, it avoids a waste condition if one pipe is adjusted and the other is affected. The auto single-control double puller and cutting are combined with the front shaping technology to mak operation more flexible. Let you economic benefit which is brought about by separately control dual pipe extruding. The diameter of the extruded pipe is from 16mm to 63mm. it can make fully use of the extruding capacity of extruder. Even if it produces small diameter pipe, it can get great output too.

| Extruder model | ET-D51/105 | ET-D55/120 | ET-D65/132 |

| Main motor power(kw) | 15 | 22 | 37 |

| Max. Capacity (kg/h) | 120kg/h | 150kg/h | 250kg/h |

| Diameter of pipe | 16mm - 63mm | ||

| Die head / pipe mould | Dual pipe die head | ||

| Vacuum calibration tank | dual pipe | ||

| Puller & cutting machine | Belt puller, knife cutting | ||

| Belling machine | Online belling | ||

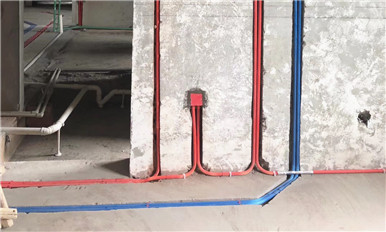

| Usage of pipe | Water , electric conduit | ||

PVC double pipe extrusion production line products are mainly used in building threading pipe, electrical pipe and so on. The first-class quality has been integrated into many years of experience. The main machine adopts conical twin-screw extruder, which improves mixing effect and high extrusion pressure. Double tube extrusion die, high production efficiency and stable blooming. Double tube vacuum sizing technology, spray cooling, to ensure the quality of pipes, single production control of the overall structure of the double tube traction mechanism and synchronous cutting, compact equipment, small spot area, and with accurate and arbitrary size of the tipping and stacking device. This production line is developed by our company in combination with the advanced technology of the end of 90 years in Western Europe, It is mainly used for the production of double PVC pipes. The main machine is sjz51 / 105 or sjz65 / 132 conical twin-screw extruder, equipped with double pipe single control stainless steel spray setting machine. The production is to avoid the waste phenomenon of one pipe adjustment affecting the other pipe. The automatic single control double traction machine and cutting are integrated with the front double setting technology, making the operation more flexible, so that you can appreciate the combination of the two pipes separately and separately It can make full use of the extruding capacity of the extruder, and even the production of small diameter pipes can reach a high output, which is safe and convenient to use. The first mock exam is mainly for electric double tube equipment such as electrical wire drawing pipe, PVC double thread extruder and double cavity with double mold, which has the advantages of good plasticizing, high productivity, high efficiency and multi function of PVC.

Electrical bushing performance

Among all the indexes required by the national standard, such as compressive property, bending property, electrical property and flame retardant property, PVC electrical casing is an important index to reflect the performance of electrical pipe, and it is also an important index to evaluate the quality of electrical casing. The indicators of electrical casing are as follows:

1. Compressive performance: it is to ensure that the electrical casing will not be flattened and meet the use requirements in the use process, especially in the case of buried concrete. The national standard requires that DF ≤ 25% for 1 min load and 10% for 1 min unloading (DF: change rate of outer diameter);

2. Bending performance: its purpose is to test the cold bending performance of electrical casing. The electric pipe is of - 15 type, that is, under the condition of - 15 ℃± 2 ℃, the electric pipe is bent by spring to 180 degrees without fracture;

3. Electrical performance: it is to detect the insulation strength and insulation resistance of pipes. When the electric pipe is loaded with water for voltage test, 2000 V voltage is applied to keep it from breakdown for more than 15 minutes, and the insulation resistance measured is greater than 100m Ω, which fully meets and exceeds the requirements of national standards.

4. Flame retardant performance: if the electrical pipe is ignited, there shall be no obvious flame propagation. After the fire source is removed, the casing flame shall be extinguished within 30s (i.e. self extinguishment time te ≤ 30s). PVC is Class B1.

Wooden pallet, PE film package.