Country/Place:Kosovo First visit time:2021-05-10 Because the PVC profile corner is most likely to be damaged during the construction and completion of the building, the use of corner strip strengthens the firmness of the wall, and can save a lot of t...

Country/Place:Kosovo

First visit time:2021-05-10

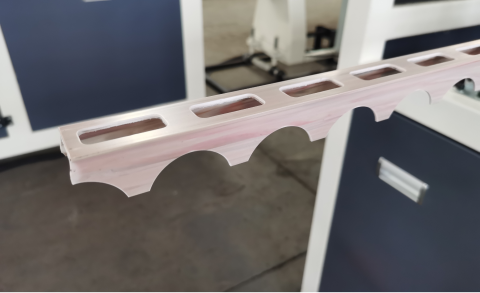

Because the PVC profile corner is most likely to be damaged during the construction and completion of the building, the use of corner strip strengthens the firmness of the wall, and can save a lot of time because of its easy construction. The corner protection strip is fast and convenient for construction, strengthens the wall corner strength, and has wide practicability. The corner protection strip has the advantages of corrosion resistance, impact resistance, anti-aging, good adhesion and full combination with putty, which greatly enhances the impact resistance of the wall corner, maintains the long-term beauty of the wall corner without being damaged, and can be constructed simultaneously with the main project. There is no need to use the guiding ruler plate in the use process, the operation is simple, the construction efficiency is 2-5 times that of the general, simplifies the construction procedure and speeds up the construction speed, The project cost is reduced and the project quality is improved.

PVC corner strip is a new type of building material specially designed for the difficult construction of wall corner, door edge strip and window corner. It is characterized by its unique environmental protection, weathering resistance and aging resistance. Its strength and toughness have made people replace steel, wood, aluminum and other traditional building materials safely. We use corner protection to cover up the lack of technology and bind the wall corners up, down, left and right. Even if a single benzene plate is accidentally cracked, it is difficult to affect the large-area falling off of the whole system. After using PVC strips, you can’t do it straight, because the thickness and size of our products are unified, and we carry 10cm grid cloth, which eliminates the complex locking process of reverse wrapping of grid cloth, increases the impact resistance of wall corners, and the perpendicularity and levelness of wall corners are very easy to achieve. In addition, it prolongs the service life of external wall insulation and improves the quality of buildings. Keep the corner permanently beautiful.

This project is the first time that the customer company has done it. Fortunately, the customer readily ordered equipment with us in the second week of connecting each other.

PVC corner profile production line includes: single screw extruder, mould, vacuum calibration table, haul-offs, on-line punching machine and cutting machine. Extruder model: SJ65 / 25 Single screw extruder motor power: 22kw

The PVC corner machine is an automated production line designed for small special-shaped materials such as PVC hard corner , internal and external corner strips, and decorative edge strips. It has the characteristics of compact structure, controllable accuracy, and convenient mold replacement. It can produce various types of PVC corner products for building wall internal and external corner protection, decorative edge corner finishing, and is suitable for multiple scenarios such as home decoration and tooling.

As the power core of the production line, the extrusion host system is mainly equipped with a single screw extruder, which is suitable for the low yield and high-precision extrusion needs of small profiles.

Screw and barrel: Screw diameters are commonly 65mm, with a length to diameter ratio of 25:1-28:1. The material is 38CrMoAlA alloy, which has undergone nitriding treatment and a hardness of HV900 or higher. It is wear-resistant and corrosion-resistant; The material barrel adopts zone temperature control, which is divided into a feeding section (120-140 ℃), a compression section (150-160 ℃), and a homogenization section (160-170 ℃). The temperature control accuracy is ± 1 ℃, ensuring that the PVC material is fully plasticized and does not degrade.

Drive and Control: Equipped with a 5.5-15kW variable frequency speed motor, the extrusion speed can be continuously adjusted within the range of 0.5-8m/min, and the extrusion rate is 5-50kg/h; Equipped with a PLC control system, it can display and adjust key parameters such as temperature and speed in real time.

The mold forming system is the core unit that determines the cross-sectional shape and dimensional accuracy of the corner protector, and the core component is a specialized profile mold.

Mold structure: Adopting a combination design of diversion cone and forming die head, the flow channel is optimized by streamline to ensure uniform distribution of the melt and avoid deviation in the wall thickness of the finished product due to uneven flow rate; The mold cavity is customized according to the cross-section of the corner protection line, with common specifications such as 20 × 20mm, 25 × 25mm, 30 × 30mm and other internal and external corner strips. It supports special surface designs with grids, patterns, etc.

Mold material and maintenance: High quality mold steel is selected, and the mold cavity is polished and chrome plated, with a surface smoothness Ra ≤ 0.1 μ m, ensuring a smooth surface of the corner protector; The mold adopts a quick disassembly structure, with a replacement time of ≤ 20 minutes, and can quickly switch between different specifications of products.

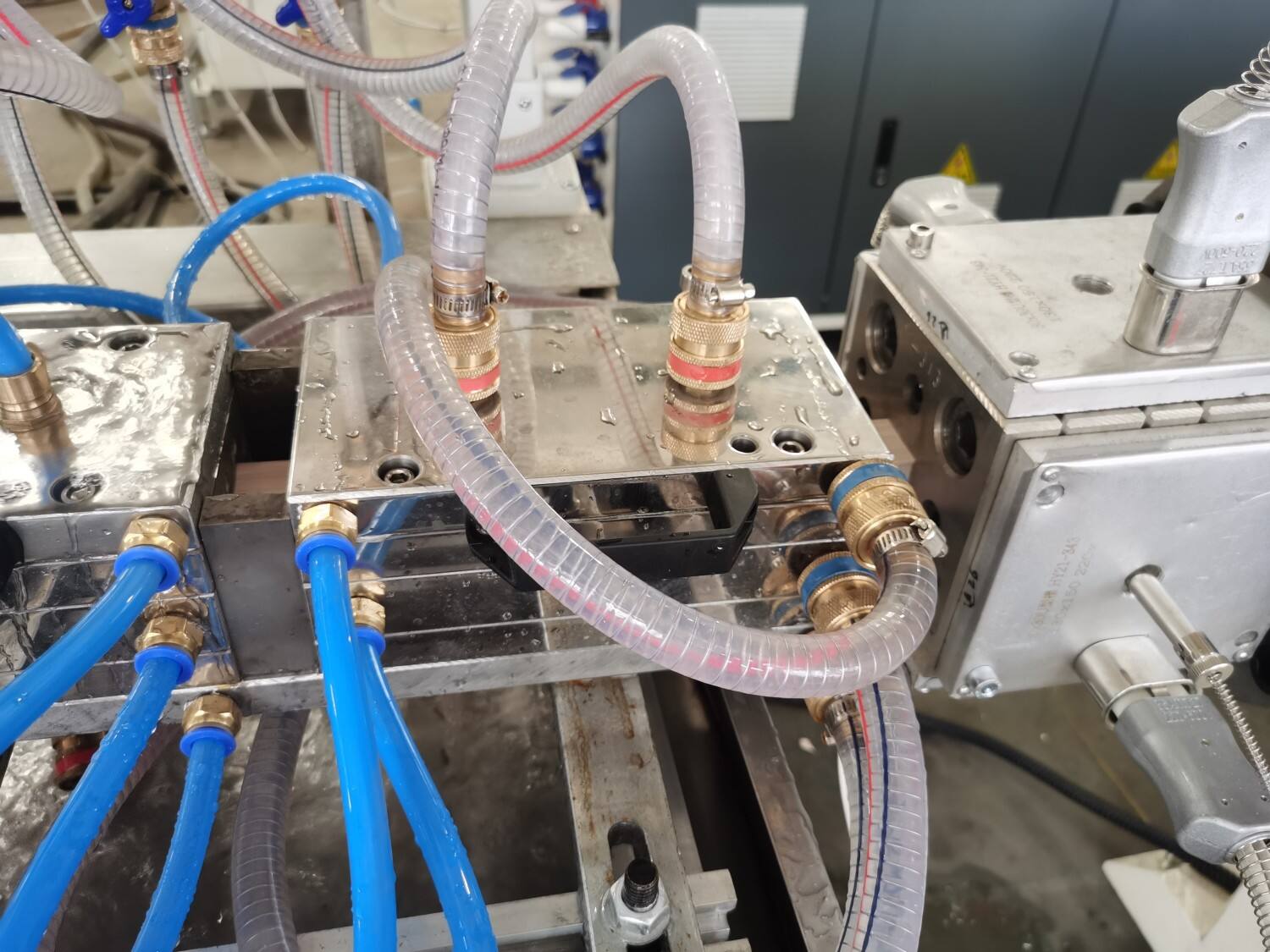

The key link for the cooling traction system to achieve the shaping and uniform conveying of the angle protection line includes the shaping cooling frame and the tracked traction machine.

Standardized cooling rack: adopts a combination of air cooling and water cooling cooling method, with small corner protectors mainly using air cooling and supplemented by spray cooling to avoid internal stress caused by sudden cooling; Some high-precision products can use vacuum adsorption shaping tanks to ensure accurate cross-sectional dimensions with a dimensional accuracy error of ≤± 0.1mm.

Crawler type tractor: adopting a dual track clamping structure, the traction force is uniform and adjustable, and the traction speed is precisely matched with the extrusion speed to prevent the protective angle wire from stretching and deforming; The traction speed range is 0.3-10m/min, suitable for different extrusion production requirements.

The cutting counting system completes the fixed length cutting and automatic counting of corner protectors, with the core component being a servo positioning cutting machine.

Cutting method: Using a small flying knife cutting machine, the blade is made of hard alloy material, and the cutting process is free of burrs and broken edges, with a smooth cut; The cutting length can be freely set through the touch screen, with conventional lengths of 2m, 2.5m, and 3m, and a cutting accuracy of ≤± 2mm.

Counting and cutting: Equipped with an automatic counting device, it automatically stops and reminds when the set quantity is reached. The cut finished products are neatly stacked on the cutting rack for easy subsequent packaging.

2、 Workflow

• Ingredient mixing: According to the formula, PVC resin and various additives are put into a high-speed mixer, hot mixed evenly, and cooled to room temperature to obtain a dry mixture;

• Automatic feeding: The vacuum feeding machine transports the dry mixed material to the hopper of the extruder host;

• Melt extrusion: The material is heated, sheared, and plasticized in a single screw extruder to form a uniform melt, which is extruded into corner wire blanks through a profile mold;

• Cooling and shaping: The raw material enters the cooling rack and is rapidly shaped by air/water cooling to form a hard corner protector with stable cross-sectional dimensions;

• Traction cutting: The traction machine uniformly transports the shaped corner wire, and the servo cutting machine precisely cuts it according to the preset length;

• Counting and stacking: The cut finished products are automatically counted and neatly stacked, packaged and stored.