Country: Vietnam First visit to our factory: 2018-09-20 Meeting for discussing PVC pipe extrusion line, dual PVC pipe: 20mm – 63mm 2 days for discussing technology, machines running, and other information. This is customer’s fir...

Country: Vietnam

First visit to our factory: 2018-09-20

Meeting for discussing PVC pipe extrusion line, dual PVC pipe: 20mm – 63mm 2 days for discussing technology, machines running, and other information. This is customer’s first investment to pipe industry, to start this project, the client have done some research in market for around 2 years. We met with customer for 2 times in Vietnam before, also the client thought to choose supplier. In 2018, the client came to visit our factory, according to our rich experience, we supplied him detailed project case, and raw material formulation direction. In May, 2019, the client decided to set up this project.

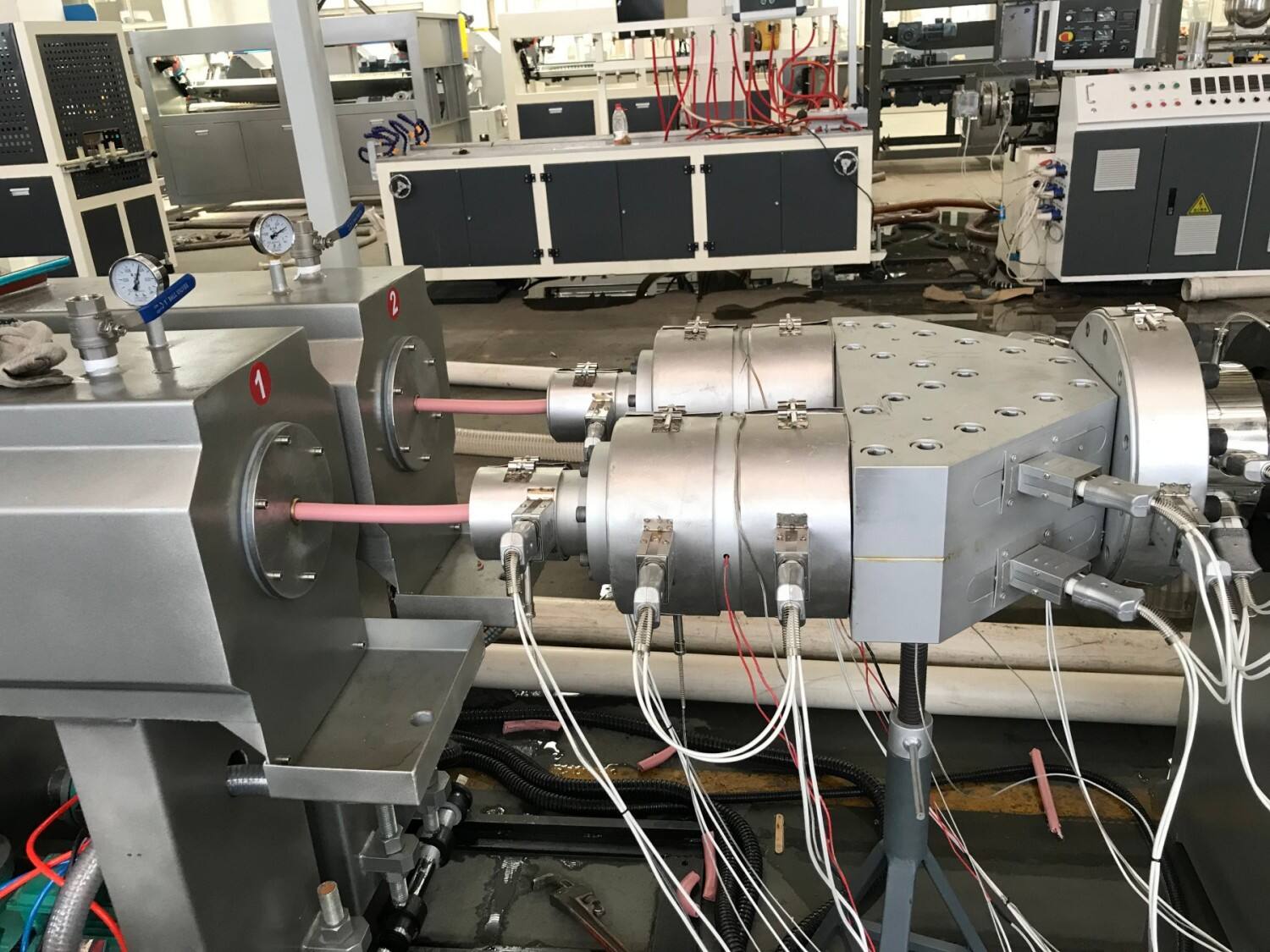

In 5th, August, 2019, the client came to our factory for checking running machines. One day, we tested complete production line includes extrusion line & belling machine.

The PVC pipe production line is an automated production line that integrates raw material processing, melt extrusion, molding and shaping, traction cutting, testing and stacking. It is mainly used to produce PVC-U, PVC-M, PVC-C and other series of plastic pipes, which are widely used in fields such as water supply and drainage, municipal engineering, building threading, and agricultural irrigation. The entire production line adopts modular design, which can be flexibly configured according to pipe specifications and output requirements, and has the characteristics of stability, efficiency, and intelligence.

1、 Core components, systems, and functions

The entire PVC pipe production line consists of five core parts: raw material pretreatment unit, extrusion host unit, forming and shaping unit, traction cutting unit, and detection and stacking unit. Each unit operates in coordination to achieve full process automation production from raw materials to finished pipes.

The raw material pretreatment unit is a prerequisite for ensuring the quality of pipes, mainly including high-speed mixers, cold and hot mixing units, and automatic feeding systems.

High speed mixer: Mix PVC resin powder, stabilizer, plasticizer, filler, colorant and other auxiliary materials according to the formula ratio. Under high-speed stirring and shearing, the material temperature is raised to 110-120 ℃ to achieve uniform dispersion of each component;

Cold and hot mixing unit: The hot mixed material enters the cold mixing machine to cool down to 40-50 ℃, avoiding high-temperature material agglomeration and completing material cooling and drying;

Automatic feeding system: Using a vacuum feeding machine, the mixed materials are accurately conveyed to the extruder hopper, and the entire process is sealed without dust leakage. The feeding accuracy error is ≤ 1%.

The extrusion host unit is the core power source of the production line, and the mainstream configuration is a conical twin-screw extruder, which is suitable for the high viscosity and low fluidity characteristics of PVC materials.

Screw and barrel: made of 38CrMoAlA alloy material, with a surface hardness of HV900 or above after nitriding treatment, and excellent wear and corrosion resistance; The unequal distance and depth design of conical twin-screw can achieve forced conveying, full plasticization, and stable extrusion of materials, effectively avoiding material degradation;

Temperature control system: adopting zone independent temperature control, the material cylinder is divided into feeding section, compression section, melting section, and homogenization section, with a temperature control range of 140-190 ℃ and a temperature control accuracy of ± 1 ℃; The machine head is equipped with a pressure sensor to monitor the melt pressure in real-time, ensuring extrusion stability;

Drive system: Equipped with a variable frequency speed regulating motor with a power range of 15-160kW, the extrusion speed can be adjusted according to the pipe specifications, and the extrusion volume range is 50-1000kg/h.

The forming and shaping unit determines the dimensional accuracy and surface quality of the pipe, mainly composed of extrusion molds, vacuum sizing boxes, and cooling water tanks.

Extrusion mold: using a dedicated spiral die head, the flow channel is optimized with streamlined design, and the melt flow is smooth without dead corners. It can be adapted to the production of pipes with different diameters from φ 16 to φ 800mm; The mold material is high-quality mold steel, polished and chrome plated, with a surface smoothness of Ra0.2 μ m, ensuring a smooth outer wall of the pipe;

Vacuum sizing box: using vacuum adsorption shaping technology, the vacuum degree can be adjusted within the range of -0.04~-0.08MPa. The outer wall of the pipe is adsorbed onto the sizing sleeve through vacuum negative pressure, and combined with circulating cooling water inside the box, it achieves rapid cooling and shaping of the pipe with a diameter accuracy of ± 0.3%;

Cooling water tank: divided into multi-stage cooling zones, controlled by water temperature gradient, gradually cooled from room temperature to low temperature to avoid cracking of pipes due to excessive internal stress caused by sudden cooling. The cooled pipes have stable shaping effect and no warping or deformation.

The traction cutting unit realizes uniform transportation and precise cutting with fixed length of pipes, including multi claw traction machine and servo cutting machine.

Multi claw traction machine: adopting a track or roller traction structure, the traction force is uniform and adjustable, the traction speed is 0.5-10mm/min, which is precisely matched with the extrusion speed to ensure uniform wall thickness of the pipe; Equipped with tension control system to prevent pipe stretching and deformation;

Servo cutting machine: divided into two types: flying knife cutting and planetary cutting. Small caliber pipes are cut with flying knives, while large caliber pipes are cut with planetary cutting. The cutting length can be freely set through the touch screen, and the cutting accuracy is ≤± 2mm. The cutting process is free of burrs and broken edges, and the incision is flat. It supports automatic counting function.

The detection and stacking unit, as a key link in controlling the quality of finished products and subsequent warehousing, includes an online detection system and an automatic stacking machine.

Online detection system: integrating wall thickness detector, outer diameter detector, and pressure testing machine, real-time monitoring of the wall thickness uniformity, outer diameter deviation, and pressure strength of pipes, and automatic marking and removal of non-conforming products;

Automatic Stacking Machine: The cut pipes are sent to the stacking area through a conveyor line and neatly stacked by a robotic arm according to the set quantity. The stacking height can be adjusted to reduce manual labor intensity and improve storage efficiency.

2、 Workflow

• Ingredient mixing: According to the formula, PVC resin and various additives are put into a high-speed mixer, hot mixed to the set temperature, and then transferred to a cold mixer for cooling to obtain a uniform dry mixture;

• Automatic feeding: The vacuum feeding machine transports the dry mixed material to the hopper of the extruder host;

• Melt extrusion: The material is heated, sheared, and plasticized in a twin-screw extruder to form a uniform melt, which is extruded into a tubular billet through a die;

• Shaped cooling: The tubular billet enters the vacuum sizing box and is shaped by negative pressure adsorption and cooling water. It is then cooled in multiple stages by a cooling water tank to form a hard pipe material;

• Traction cutting: The multi claw traction machine uniformly pulls the pipe, and the servo cutting machine precisely cuts according to the preset length;

• Inspection and stacking: The online inspection system completes quality inspection, and qualified pipes are sorted and stacked by an automatic stacking machine, packaged and stored.